Understanding the know-how of the new engines you’ll be selling is vital, but being alert to the new technology you’ll be competing against is every bit as important.

By this time next year, every new farm vehicle sold in the U.S. that’s powered by a diesel engine over 175 horsepower will be Tier IV compliant or use EPA allowed emission credits. That’s not news.

What is news are the distinct differences in the technologies that will be powering those new engines. Farm equipment makers are clearly taking divergent paths to meet the new, tougher emission standards required in both the U.S. and Canada that will take effect in January 2011. But keep in mind that these are only interim requirements. The final Tier IV standards that kick in in 2014 are even more stringent.

The goal of the new regulations is to reduce the amount of nitrogen oxides (NOx) by 45% and soot, or particulate matter (PM), by 90%. NOx is produced by the high combustion temperatures inherent in diesel engines. The higher the temperatures, the more NOx is emitted through the engine’s exhaust. PM is a byproduct of non-combusted diesel fuel.

Diesel Engine Choices

So far, engine manufacturers have zeroed in on two engine technologies that either prevent the production of NOx or eliminate it after it’s produced. Both are used to meet emission requirements for on-highway diesel vehicles. They include cooled Exhaust Gas Recirculation, or EGR, and Selective Catalytic Reduction, or SCR.

In many cases, the new emission control systems require use of ultra-low sulfur diesel (ULSD). This was introduced by refiners for use in on-highway vehicles in June 2006. At this point, farm equipment maker John Deere and Cummins Inc., which builds diesel power supplies for Versatile equipment as well as for other manufacturers, have opted to go the EGR route.

AGCO, on the other hand, came out the gate early announcing at their dealer meeting in February 2009 that it would be adapting the new SCR technology for its high-powered engines. Case IH announced in recent weeks that it too will be utilizing SCR technology on its interim Tier IV engines.

When all is said and done, somewhere down the road, don’t be surprised if the equipment makers adopt a combination of both of these technologies, depending upon the engine application and horsepower for final Tier IV.

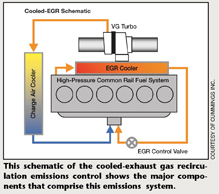

EGR Approach. Cooled EGR isn’t new and has been used by several engine manufacturers to meet the progressively lower emission levels required through Tier III. EGR works by cooling the exhaust gas and reintroducing it into the engine cylinder. Because the gas has a lower 02 content and is cooled, in conjunction with precise fuel injection, it is able to control NOx.

This system has worked well for on-highway applications because a high volume of air is available to cool the engine with the additional heat rejection needs of EGR. In off-highway applications, a larger cooling package — fans and radiators — may be required to produce the cooling required to maintain the temperatures needed to optimize EGR systems. The additional cooling required may result in some power loss as energy is siphoned off from the engine to the cooling system.

To capture the particulate or soot generated by the combustion of diesel fuel, both EGR and SCR require aftertreatment. These systems may also require an “active” particulate filter that requires regeneration or cleaning to maintain its effectiveness.

SCR Systems. Diesel engines utilizing SCR capture and treat the NOx by injecting diesel exhaust fluid (DEF) — a blend of urea and ionized water — into the engine’s exhaust stream. Oxygen combines with the urea to form ammonia and carbon dioxide, which react with the NOx to produce the harmless byproducts of nitrogen gas, water and CO2.

The obvious difference equipment dealers and farmers will see is the SCR system is literally bolted on to the engine. In other words, it is an entirely separate system apart from the engine.

SCR also requires sensors to assure that the amount of DEF is adequate to control NOx emissions. With AGCO’s system, if an operator doesn’t maintain the proper level of DEF, or tries to defeat the system by adding water, the sensor automatically derates the engine to 50% of power until the system returns to proper operating conditions.

Know Your Competition

According to Duane Nelson, director, Global Brand Management for Case IH, “Both exhaust gas recirculation (EGR) and selective catalytic reduction (SCR) systems lower emissions of nitrogen oxide and particulate matter for cleaner engine output.”

But dealers will be the first to say that farmers don’t buy tractors, combines or self-propelled sprayers and windrowers for their emission control capabilities.

According to the equipment manufacturers, emission control is only part of the story when it comes to the new diesel engines they’re building. The fact is, they’ve taken the opportunity to design engines that are more fuel efficient and offer other benefits than their predecessors.

Where dealers will need to be especially alert is the differences between the two approaches — SCR vs. EGR — both of which are claimed to be “farmer friendly” and offer a variety of operator advantages.

To get a handle on how the manufacturers will be positioning their interim Tier IV engines, Farm Equipment offered each of the high-horsepower tractor makers the opportunity to present their case, and four of them — AGCO, Case IH, John Deere and Versatile with Cummins — took us up on it. Here’s what they have to say.

Making the Case for Exhaust Gas Recirculation — EGR

Farm equipment manufacturer John Deere and engine maker Cummins, which is building the engines for Versatile, have determined that a cooled exhaust gas recirculation (EGR) system is the best approach to complying with interim Tier IV emission regulations as well as providing other operational benefits for the farmer.

What EGR Offers. Steven Meinzen, integration specialist for John Deere, says that the company will be building on its already established Tier III PowerTec Plus engine platform that includes cooled EGR for NOx control with the addition of an exhaust filter for reducing particulates. The line-up will include Deere’s six-cylinder engines, which feature a four-valve cylinder head, high-pressure fuel system, variable geometry turbocharger (VGT) and air-to-air after cooling.

Cummins meanwhile is developing its QSB6.7 engine to power Versatile’s new 190- and 220-horsepower tractors along with the larger QSC 8.3-liter, QSM 11-liter and QSX 15-liter engines for the Versatile tractor range.

According to Meinzen, John Deere researched many different technologies, and from a global perspective, believes that cooled EGR is the best approach for meeting interim Tier IV emissions regulations.

Both companies say they are able to “leverage” their previous experience with Tier III EGR systems and further refine them to meet Tier IV performance requirements.

“Since 2005, we have used EGR technology reliably in agriculture, construction and forestry applications. Add an exhaust filter that contains a diesel oxidation catalyst (DOC) and a diesel particulate filter (DPF), and we believe it offers the best interim Tier IV solution for reducing PM emissions,” Meinzen says.

Cummins rolled out its interim Tier IV engines for agriculture last month at the Ag Connect Expo in Florida.

Both Deere and Cummins claim proprietary designs for various components that make up the emissions system.

Rob Neitzke, director of Global Off-Highway Business for Cummins, describes its emission system as including the company’s direct flow air filtration for a more compact installation with the same filtration efficiency. “The cooled-EGR system is complemented by Cummins VGT turbocharger with a sliding-nozzle design. This continuously varies the airflow boost to match engine rpm and load demands. The Tier IV interim engines also feature a crankcase ventilation system with a high-efficiency coalescing filter to maintain ultra-clean engine operation.”

Adam Reid, marketing manager for Versatile, adds, “Versatile has been working with Cummins on the development and testing of Tier IV technology in a Versatile 535 for several years. Their 174-751-horsepower engines meet the 90% PM and 45% NOx reductions achieved at Tier IV interim. These technologies are designed and developed for off-highway yaw while leveraged from the Cummins on-highway experience. They have also created a particulate filter with the same acoustic features of a muffler, thereby replacing it.”

Why Users Will Benefit. Besides meeting interim Tier IV air emission regulations, the EGR system offers a host of other advantages, according to Deere and Cummins. In terms of customer benefits, both companies report that operator’s can expect an up to 5% fuel economy improvement depending on rating and duty-cycle. “In addition to a fuel economy improvement,” says Reid, “our prototype installations with the Cummins variable geometry turbocharger have demonstrated improved engine response.”

Deere’s Meinzen adds, “We’re confident that our fuel economy position attained with Tier III will be maintained with the use of only one fluid — diesel. The cooled EGR and exhaust filter approach is the simple approach and has a proven track record throughout Tier III.

“Our EGR engines operate efficiently with traditional low-sulfur diesel as well as biodiesel blends, providing optimal performance and fuel-choice flexibility.”

In addition, both manufacturers say that it’s an advantage because they design and manufacture a complete integrated system.

“It’s a more operator-friendly technology and less complex to maintain when compared to SCR systems,” Meinzen says. “It’s simple for the operator and is part of an integrated vehicle design.”

He adds that John Deere designs, manufactures and services the engine, drivetrain, exhaust filter, ECU, cooling, and other vehicle systems as part of a complete equipment package. “Cummins offers an advantage for Versatile in that they manufacture and integrate the complete system from air-intake to the exhaust after treatment,” says Versatile’s Reid.

What Dealers Can Expect. “Clearly, Interim Tier IV brings changes,” says Meinzen. In summarizing the service conditions required for Deere’s engines, he says, for the most part, current engine maintenance intervals will remain unchanged. The oil change interval will be the same as that for Tier III engines at either 500 or 250 hours.

“One noticeable difference will come with the addition of the exhaust filter. While the regulations require an exhaust filter ash service interval of 4,500 hours minimum for engines 174 horsepower and greater, John Deere will provide a 5,000 hour ash service interval.”

Meinzen also stresses that, while the type of engine oil and diesel fuel have always been important, the technologies needed to meet interim and final Tier IV emissions regulations make them even more so. With the introduction of the exhaust filters, the type of engine oil used can have a significant impact on the proper functioning and service life of these devices.

“Ash will collect in the exhaust filter over time. CJ-4 oils with reduced trace metals content are also required to reduce ash accumulation and increase exhaust filter service life for Interim Tier IV,” he says. The CJ-4 oils can also be used in non-IT4 or older engines.

Reid says that similar service conditions hold true for Cummins engines in Versatile vehicles. “The day-to-day maintenance between Tier III and Tier IV will remain unchanged, as will the oil change maintenance intervals. A very infrequent service event will be ash cleaning of the Cummins particular filter.”

“Any additional maintenance required for Tier IV products will be more than offset by reduced operating costs with fuel efficiency improvements,” says Reid. “This efficiency improvement is a major benefit to the customer and one of the major reasons we believe we have chosen the correct solution.”

A Final Word. “Most manufacturers chose a different path to meet Tier III emissions regulations,” says Meinzen. “We took the cooled-EGR approach and ended up building the most fuel-efficient tractor ever tested. In fact, the fuel-efficiency record the Deere 8430 set at the Nebraska Tractor Test Lab established the standard for total-vehicle efficiency. That same Tier III technology is used on our Interim Tier IV engines. Initial testing indicates our cooled EGR for NOx reduction and exhaust filter for PM reduction will have a very minimal impact upon overall fuel economy.”

He adds that when total installed costs of each solution are considered, the costs are very similar. “The SCR solution can allow an engine manufacturer to use lower base-engine technologies. However, when you consider the other parts and components associated with SCR — DEF storage tank, anti-tampering devices, DEF tank level indicator, DEF tank filter, DEF tank heater and heated lines between tank, control unit and doser, John Deere doesn’t believe SCR provides a cost advantage over our cooled EGR exhaust filter solution,” Meinzen says.

“When you add in the second fluid (DEF), cost of a second fluid, availability of a second fluid, storage concerns of a second fluid and the fact that our total fluid consumption will meet or be better than the SCR solution, we’re confident our cooled EGR and exhaust filter solution is the right technology.

“For now, the John Deere Interim Tier IV single-fluid cooled EGR solution is the right technology.”

Making the Case for Selective Catalytic Reduction — SCR

Despite its relatively short history on the road and in the field, selective catalytic reduction (SCR) is the choice of both AGCO Corp. and Case IH for meeting the emission requirements for their interim Tier IV engines.

While it’s a relatively new approach, it isn’t an unproven technology. “This is the same technology that the automakers are using with the new diesel pickup trucks as well as several manufacturers of on-highway trucks like Mercedes-Benz, Volvo and Detroit Diesel,” says Jason Hoult, AGCO’s product marketing manager for high-horsepower tractors.

With a year under its belt, AGCO says the SCR technology, which they call E3, is being accepted more quickly than expected. “We had several large dealers who did not think their customers would accept it as quickly as they did. So they ordered the EGRs early on and it wasn’t that long before they started switching over to the E3’s. What we found is as we got the message out, it was something farmers were willing to accept and wanted,” says Hoult.

What SCR Offers. “SCR technology represents the best approach for large tractors where fuel efficiency and maintenance costs are the most important competitive factors,” says Duane Nelson, director, Global Brand Management for Case IH. “SCR is a cool running, quiet system that’s separate from main engine function and does not compromise horsepower or torque. And it doesn’t interfere with engine performance, but actually improves it.”

Nelson adds that by utilizing SCR technology to meet the 2011 standards, Case IH already invested in the R&D required to achieve final Tier IV requirements, which all manufacturers must meet by 2014. “Possessing this technology allows us to focus our research and development investments into the next generation of tractors,” he says

While the impetus may have been a government mandate to reduce diesel engine emissions, fuel economy was the real driver of why the two equipment makers chose to go with SCR.

According to Jason Hoult of AGCO, SCR technology allows the engine to concentrate on optimizing combustion and efficiency without worrying about gas emissions, as all of the exhaust products are cleaned after they leave the engine. “The result is the engine uses up to 15% less fuel than comparable Tier III engines while delivering the same power output,” he says.

Because SCR systems are a departure from previous emission control approaches, AGCO introduced SCR on Tier III engines 2 years before the emission regulations will take effect. “We wanted to launch it early to provide our dealers and customers with experience with the new system,” Hoult says.

“We also needed to start slowly into the diesel exhaust fluid (DEF) availability. We wanted to piggyback on to what the trucking industry was doing. We knew it would take a year or so to get the farmers and dealers into the mindset of what SCR is.”

According to AGCO, tractors outfitted with SCR systems are easily meeting the Tier III standards. “There are some additional costs to meet the Tier IV emission levels, but we didn’t want to burden customers before it’s necessary. It will require injecting more diesel exhaust fluid (DEF).”

Why Users Will Benefit. “This is really the first time that we feel that emission regulations are giving something back to the farmer,” Hoult says of the advantages offered by the new engines with SCR. “Every other time we’ve had to lower emissions, it’s been a tradeoff in power or productivity, and customer costs went up without any corresponding benefits.”

Hoult says that the results of recent Nebraska Tests verified a fuel savings of 4-16% compared with competitive engines without SCRs.

“This gives you an idea of what the SCR system allows us to do because we’re tuning the engine for power and economy, not for controlling emissions,” Hoult says.

“It’s the most farmer friendly approach because with a SCR engine, the only thing the farmer needs to be concerned with is keeping the DEF tank full. It’s another task, but it’s not like it’s something they don’t do already. They also have to keep the washer bottle, radiator coolant and fuel tank full, too.”

In addition to improved fuel economy, Nelson of Case IH says they elected to go with SCR for its improved reliability because the SCR system allows the engine to reduce the heat rejection of many internal engine components.

“We believe the SCR system also offers customer unbeatable durability because it reduces particulate matter inside the engine, which also reduces clogging and excludes any regeneration intervention,” he says, referring to the regenerative type filters required with EGR systems to collect soot.

They also point to the fact that SCR engines are able to work with all grades and varieties of diesel fuel. “Catalyst substances are not influenced by the presence of traditional substances in the fuel, such as sulfur,” Nelson explains.

What Dealers Can Expect. From the dealers’ standpoint, Nelson says that while both EGR and SCR systems lower NOx emissions and particulate matter for cleaner engine output, SCR should offer the advantage of longer service intervals because the combustion process preserves oil’s physical properties reducing maintenance requirements and related downtime.

“There is a requirement for our dealers to get a couple special tools, but it’s nothing exotic,” Hoult explains.” It’s just a couple of special sockets because some of the componentry, like the quality sensor, must be tamper-proof. It requires a special tamper-proof socket to remove it.”

Otherwise, he says, they are providing AGCO dealers with a DVD dedicated to the E3 system that shows where the components are and what they do.

“It’s another system that the service mechanic will need to understand. But it’s an injector, pump and a tank that has a computer that controls it. It’s not rocket science.”

Hoult also points to an opportunity for dealers to develop a new revenue stream in becoming a supplier of DEF. “We supply it directly from AGCO Parts, but there’s no reason a dealer couldn’t handle it like a lot of them do for oil. It’s an additional fluid that the customer’s going to need. But dealers will need to be on the front of that curve if they’re going to capture that opportunity,” he says.

A Last Word. “Consensus among the industry’s leading engineers is that tractor manufacturers will need to use the SCR after-treatment process by 2014,” says Nelson of Case IH. “While there are other interim solutions, Case IH believes SCR is the most efficient way to meet EPA standards. Any other approach would be a short-term solution. SCR is the best guarantee that customers will have a reliable, cost effective, state-of-the-art tractor.

Hoult adds that there are two major advantages of SCR systems. The first is with SCR the engine is tuned for power, not for emissions. The biggest difference customers and dealers will see between the two systems is how big and what type of particulate filter will be needed to meet Tier IV standards.

“The beauty of the SCR system is it may not require a particulate filter at all. And if it does, it won’t need to be an active one and it will be very small.”

SCR systems require additional components, including an injection system, separate tanks, the diesel oxidation catalyst (DOC) and particulate filters that are required for both SCR and EGR systems.

“But customers will see savings on the DOC and particulate filter with SCR,” Hoult says, “because they don’t have to be as large or as complex. Customers will also save on the engine side because the engines don’t have to be nearly as complex. SCR systems don’t require the variable-geometry turbochargers, the computer controlled fans or as large a cooling package. Overall, it’s really a tradeoff between the two systems.”