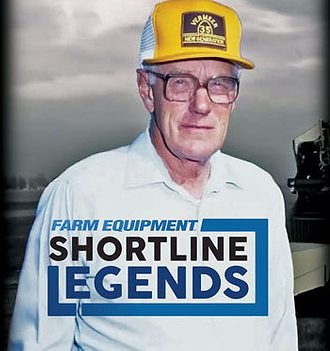

In 2023, Vermeer Corp. celebrates its 75th anniversary. The company’s roots go back to World War II, when founder Gary Vermeer was looking for a way to speed up the unloading of corn in a tight labor market. The result was Vermeer’s invention of a mechanical wagon hoist.

“He initially built that for his own use,” says Mary Andringa, Gary Vermeer’s daughter, former CEO and current board chair emeritus in a 2018 podcast with Farm Equipment editor/publisher Mike Lessiter. “He and his father were doing corn picking for a number of neighbors during World War II. They were trying to find out a better way to get from one farm to the other quickly, and a part of that was an easier way to unload the corn out of the wagon.”

Andringa added that it wasn’t long before neighbors were asking Vermeer for a hoist of their own.

“He went to a blacksmith shop in Pella, Iowa, and tried to do an OEM arrangement with them for a while,” Andringa says. “That didn’t really go as well as he thought it would. So, 1948 was when he decided to start his own manufacturing business with his cousin Ralph Vermeer.”

The start-up had only 1 additional employee. Ralph unfortunately passed away after about a decade in the business.

Farmer & Tinkerer

In August 2019, Farm Equipment published an article about the company’s innovations and how Gary Vermeer teed up the company for success as an equipment innovator. In that story, Andringa recalled her father’s penchant for finding better ways of doing things.

“He was a farmer, but a ‘tinkerer’ too, and always looking for better ways to do things,” she says. “He put a cab on a John Deere in 1939, and there was an article in the local paper that showed him in the tractor. It said, ‘When everybody else was on their tractor with purple cheeks and hands because it was so cold, Gary Vermeer was riding nicely along in his cab.’ In those days, nobody had cabs on tractors.”

Mindi Vanden Bosch, Mary Andringa’s daughter and Vermeer’s current vice president of operations, shared how all of the company’s innovations can be traced back to Gary Vermeer’s farmer sensibilities.

“I always like to tell our new dealers that what I think is exciting is, a lot of times, his first inventions after the wagon hoist and a few others are actually our industrial side of the product,” she says. “But a lot of them were because he was trying to make it easier on the farm. So, at the end of the day, he still had the farm in the background of his mind all the time.”

“Gary laid the groundwork for the company. He had strong principles. No debt was a strong principle, and it was unusual. Today, I have no debt. I got those principles from dealing with Vermeer…” – Vermeer dealer John Vos in the book "In Search of a Better Way"

Finding Better Ways

Two of those inventions include the company’s tiling trencher and stump cutter, Vanden Bosch adds. According to the book In Search of a Better Way: The Lives and Legacies of Gary and Matilda Vermeer by Carol Van Klompenburg and Donna Biddle, tiling was necessary to improve soil drainage. It meant digging trenches to lay the tile, which was often fired clay pipe that would carry water away from the field during wet weather. In 1951, Vermeer created the Model 12 PTO-driven tiling trencher, which launched the company’s line of tiling trenchers. According to the Assn. of Equipment Manufacturers (AEM), these were followed in the 1960s and 1970s by mechanical ride-on trenchers, which led to today’s hydrostatic utility and track trenchers.

The book described Vermeer’s invention of the stump cutter as a happy accident. In the 2018 podcast, Bob Vermeer, Gary’s son and the former company CEO and board chair who passed away in 2022, agreed. “The idea came from a local farmer who brought it to Vermeer. They developed a prototype, and they had a prototype that they assumed would be most effective cutting forward and backward across the stump. As the story goes, someone hit the wrong lever and it swung side to side, and they realized it was 5 times more effective cutting a stump that way.

“And, to this day, that is how a stump cutter works. It sweeps back and forth across the stump. So it’s quite interesting in the history of the company that the heritage of our industrial side of the business actually predates the invention of the round baler, which is the single most iconic invention in Vermeer’s history.”

Round Baler Breakthrough

Gary Vermeer’s search for better ways of doing things led to the invention of the aforementioned round baler — a tool that dramatically reduced the backbreaking labor required to bale hay by hand. According to In Search of a Better Way, old-school haying usually required at least 3 men to get the job done, and unless a farmer had sons or other relatives to help, they had to turn to neighbors for assistance. Timing was also important, as alfalfa has to be cut before it flowers and left to dry for at least a day in the field. Because it loses some of its nutrient value if it is exposed to rain, farmers needed to capitalize upon fair weather. It was a process typically done 3 times each summer.

“I remember that personally because when I was growing up, we were expected to help in the summer,” Bob Vermeer says. “First, you had to rake the hay. Then the actual putting up the square bales — you had someone drive the tractor that made the square bales. Then you had someone on the wagon who was stacking the bales. Then, when that wagon was full, you took that wagon to where the barn was and you took the bales off, put them in an elevator, and they went up in the elevator into the barn, and you had someone in the barn.”

According to Bob Vermeer, the baler’s inspiration allegedly occurred during a walk Gary Vermeer was taking with friend and fellow farmer Arnold Van Zee. Van Zee was considering selling his cattle because of how hard it was to put up hay — it was at least a 4-person job.

Vermeer explained that his father worked with Arnie Mathes, a man with a sixth-grade education but “a brilliant person” on the development of the round hay baler. Mathes had been working in the Vermeer experimental department. And experiment they did. The book says their first prototype wouldn’t turn a bale. Vermeer made use of some old fence posts that helped solve the problem. Curved fingers also helped get the bale rolling.

The first Vermeer round baler formed a bale of hay 6 feet wide and 7 feet in diameter, weighing more than a ton. The book explains that machine reduced baling from a 3-5-man chore to a 1-man operation. “The invention made the entire process easier: harvesting, storing and feeding.” It also mitigated the need to shelter the bales, as they were tightly wound and shed water.

That first year, Vermeer filled 300 orders, and all were delivered by May 1972. Following the baler’s introduction, Vermeer nearly quadrupled in sales by 1974. To avoid having the baler idea taken over by larger manufacturers, Vermeer built a dealer network of farmers, avoiding typical distribution channels while getting the product into the hands of farmers.

Not Just Improved

Mary Andringa said Gary Vermeer was not interested in only improving other’s designs. “Gary’s premise was to design something new — not on the market. For example, I remember Dad saying, ‘We found this way to be able to dig around a tree, pick it up and transplant it. If you can have a tree in your yard that’s already 10 inches in diameter, wouldn’t that be great?’” That resulted in the introduction of the Vermeer Tree Spade in the 1960s.

In a September 2017 Farm Equipment article, Vermeer Executive Vice President and CMO Mark Core described an R&D group at Vermeer — Forage Innovations — that still traces its roots back to Gary Vermeer’s attitude about product design.

“Their focus is on things that don’t exist in the marketplace today vs. our other product development group that focuses daily on bringing better balers, better mowers and better rakes to market,” he says. “But our Forage Innovations team is an interesting balance because we know we are going to be testing some concepts that aren’t initiated by our customers.”

That Forage Innovations group helped bring to market an industry first — the Vermeer ZR5-1200 self-propelled baler — in 2018.

Today & Tomorrow

Gary Vermeer passed away in 2009 at the age of 90, but not before passing on the wisdom and work ethic necessary for his heirs to grow the company to the 75-year mark and position it for the future. Grandson Jason Andringa (Vanden Bosch’s brother) has been president and CEO of the company since 2015. Daughter Mary Andringa and granddaughter Vanden Bosch continue to guide the company, as well.

“With the guiding principle of treating other people how you’d want to be treated yourself, we’ve created a culture over the last 75 years of making a real impact on the way work gets done that continues to drive our company forward,” Jason Andringa says of the company’s anniversary. Vermeer operates 8 facilities on 6 continents with about 4,000 employees and provides service and support in over 60 countries via more than 600 dealers.

Nominate a Future Shortline Legends Hall of Famer

Submit a nomination for the next class! The Shortline Legends Hall of Fame recognizes the achievements of individuals who advanced the innovations and success in shortline/independent equipment innovations.