Farm Equipment

Future-Planned Facilities

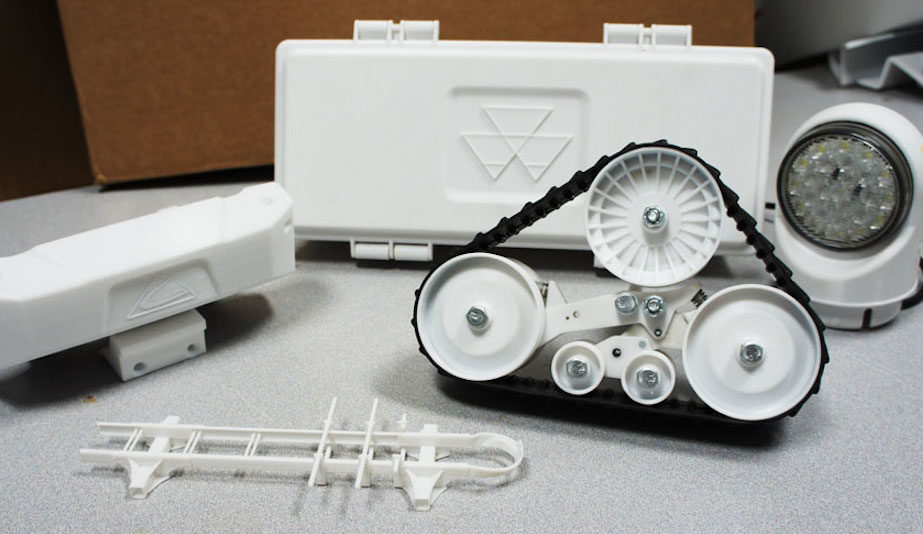

Additive manufacturing, better known as 3-D printing, has been causing a stir in the manufacturing field for nearly 20 years, but today the computer-driven process by which parts are created by successive layering of various plastic and metal components has quietly become mainstream in the design shops of major agricultural equipment manufacturers.

In early March, CNH Industrial announced availability of its first 3D-printed spare plastic parts — four items used on buses and farm equipment. At the time of the release the company said the additive manufacturing process makes it possible for local, on-demand production of spare parts, which reduces the demand for large parts inventories and allows for rapid, as-needed, economic production of low-volume items.

While the popular ideal of the local farm equipment dealer printing out spare parts on demand has been the goal of common wisdom throughout the development of 3-D printing, Paolo Pantalei, CNH Industrial’s parts life cycle director says, “I think we are pretty far away from this scenario.”

Pantalei says additive manufacturing is a game changer at the engineering and design phase of manufacturing, but the limited number of materials compatible with 3-D printing, and the cost per unit aren’t currently feasible for widespread parts production. Also, 3-D printers are rather small devices, limiting the overall size of parts they can manufacture.

“Where I find it useful is in producing low-volume parts for our machines in the later stages of their life cycle,” Pantalei explains. “We may have a 30- or 40-year old machine…