Advertise Follow Us

Farm Equipment

View Archived Issues

February 2016

Volume: 54

Edition: 2

Dealership Minds: Profile of a Successful Dealership

-

Table of Contents

Table of Contents

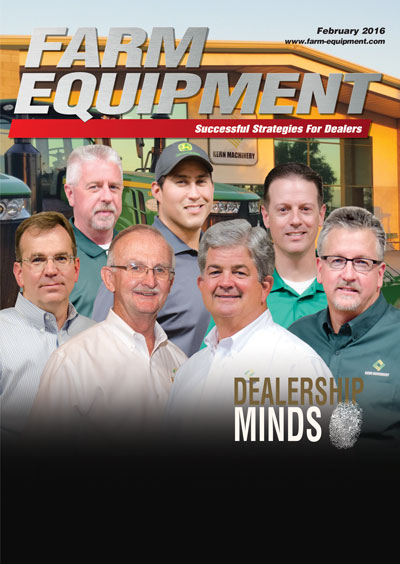

Dealership Minds 2016 Overview: Kern Machinery

Adapt and adapt again is this dealership’s mantra as it thrives in California’s highly diverse and rapidly changing ag environment.Read More -

Featured Articles

Featured Articles

Dealership Minds 2016 Overview: Kern Machinery

Adapt and adapt again is this dealership’s mantra as it thrives in California’s highly diverse and rapidly changing ag environment.Read More -

Online Extras

Online Extras